Manufacturing has undergone major transformations over the years, with advancements in technology shaping the industry in significant ways. One of the most notable developments in recent years is the rise of prompt engineering, which is set to play a key role in the future of manufacturing.

What is Prompt Engineering?

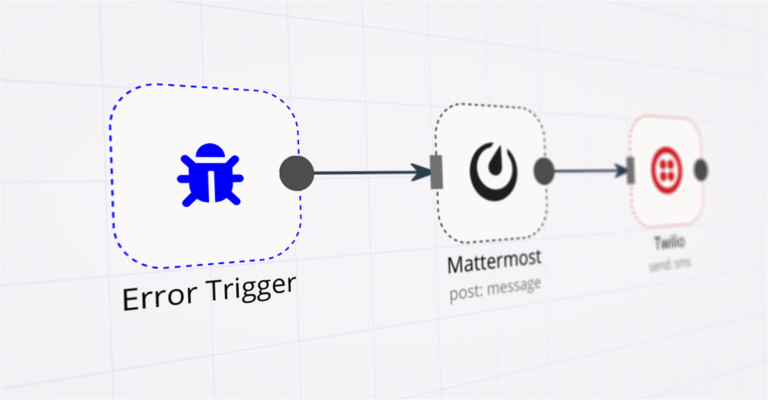

Prompt engineering refers to the use of cutting-edge technologies and processes to accelerate engineering and manufacturing activities. It involves the integration of automation, artificial intelligence, and data analytics to streamline production processes, improve efficiency, and reduce time to market. Prompt engineering encompasses a range of technologies, including 3D printing, robotics, Internet of Things (IoT), and virtual simulation, among others.

The Impact on Manufacturing

The adoption of prompt engineering in manufacturing has the potential to revolutionize the industry in several ways:

- Increased Efficiency: Automation and AI-driven processes can optimize production workflows, leading to higher productivity and reduced downtime.

- Customization: 3D printing and other advanced manufacturing technologies enable greater customization and personalization of products, meeting the growing demand for bespoke goods.

- Cost Reduction: By streamlining operations and minimizing waste, prompt engineering can drive down production costs, making manufacturing more competitive.

- Agility and Flexibility: The ability to quickly adapt to changing market demands and rapidly prototype new products gives manufacturers a strategic advantage.

The Future Outlook

The future of manufacturing is moving towards a more agile, responsive, and tech-driven landscape, and prompt engineering will be at the forefront of this transformation. As technology continues to evolve, manufacturers will need to embrace digitalization and automation to remain competitive in the global market.

Furthermore, prompt engineering will also pave the way for new business models, such as on-demand manufacturing and digital supply chains, creating opportunities for innovative approaches to production and distribution.

Challenges and Considerations

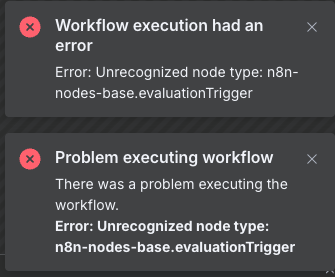

While the potential benefits of prompt engineering are clear, there are also challenges that need to be addressed. These may include concerns about job displacement due to automation, cybersecurity risks associated with connected manufacturing systems, and the need for upskilling the workforce to operate and maintain advanced technologies.

Manufacturers will also need to consider the ethical and environmental implications of adopting new technologies, ensuring that sustainability and social responsibility are integrated into their prompt engineering strategies.

Conclusion

The rise of prompt engineering represents a new chapter in the evolution of manufacturing, promising greater efficiency, flexibility, and innovation. Embracing these technologies will be crucial for manufacturers looking to stay ahead in an increasingly competitive and dynamic industry.

As we move into the future, prompt engineering will continue to reshape the way products are designed, produced, and delivered, setting the stage for a new era of manufacturing excellence.